Why Strain Relief Matters

It’s late at night on an unfamiliar street, where I have just driven out to help a friend change a flat tire. Of course, the donut is deflated too but, not to worry, I have my trusty Slime brand compressor. I plug it into the 12 V cigarette lighter and roars to life, only to start to sputter. Only by continually wiggling the cord could we inflate the tire and send my friend safely on her way. The symptoms of poor engineering were familiar.

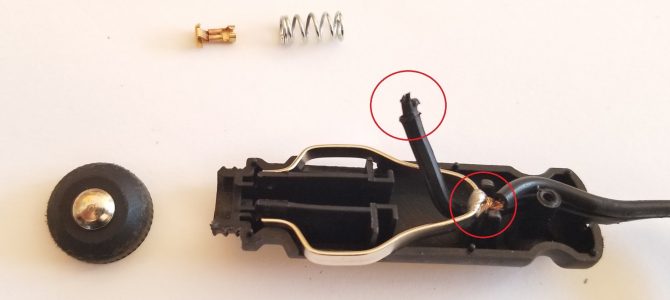

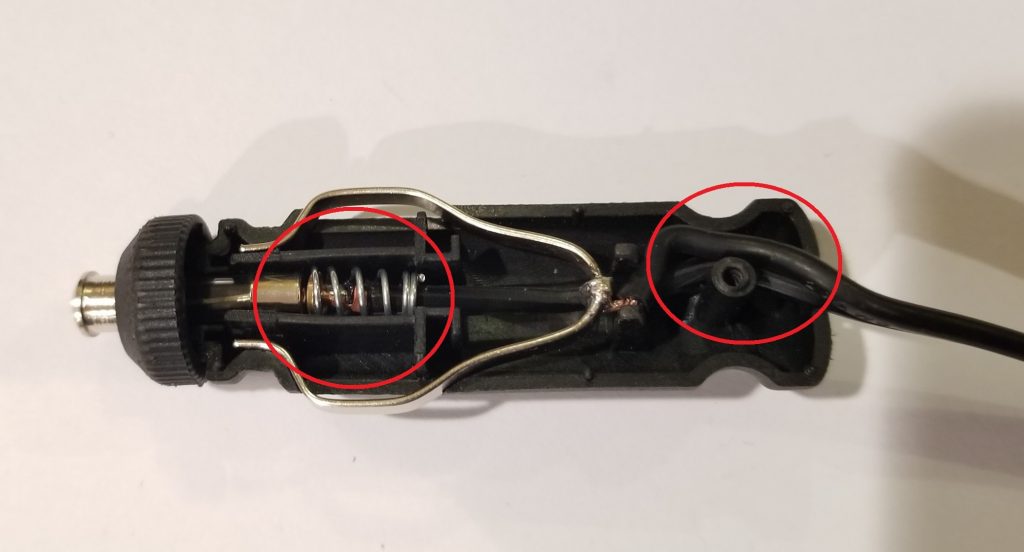

I dissembled the plug and found the wire connected to the positive terminal (connected to the tip) sparked, melted and disconnected and the negative wire hanging on by a few strands. While I am sure Slime has thought about the mechanism of their pump, it’s obvious that no one considered the reliability of the humble plug, despite proudly mounding their logo onto it. It’s failing are multiple:

- Pushing it into the socket pushes the tip and fuse inwards against the spring and, for lack of a better word, “squnches” the positive wire in and out. It has no chance of survival.

- There was no evidence that this connection was even crimped properly to the wire.

- Likewise, compressing the wings during insertion wiggles the negative wire.

- There is no strain relief where the cord exits the plug. The gentle detour does not provide any protection.

- Lastly, as a further example of cheapness, there is no LED to help indicate that the plug is receiving power, before attempting to operate the pump.

Years ago, when I was teaching MIT’s sophomore level 2.007 design course, where students build competing robots, I would wander through the lab randomly tugging on the wires and invariably “breaking” students’ robots. This was not a popular activity, but my usual response was, “Add some zip ties, it’s better I break your robot now than it fails during the final competition.” I wish Slime’s engineers had learned this lesson.

Slime’s pump’s plug is a part destined to fatigue, spark and fail. And on a safety product this is absolutely unacceptable. Better plug designs, where the cord is firmly clamped and the wires connect to fixed terminals, certainly exist for only a minor increase in cost.

This highlights the importance of not “value engineering” to cut costs and corners and keeping a sharp eye on even the simplest component, as they may become a product’s Achilles heel.